Introducing Our Newest Capability: Flatbed Laser Cutting

Introducing Our Newest Capability: Flatbed Laser Cutting

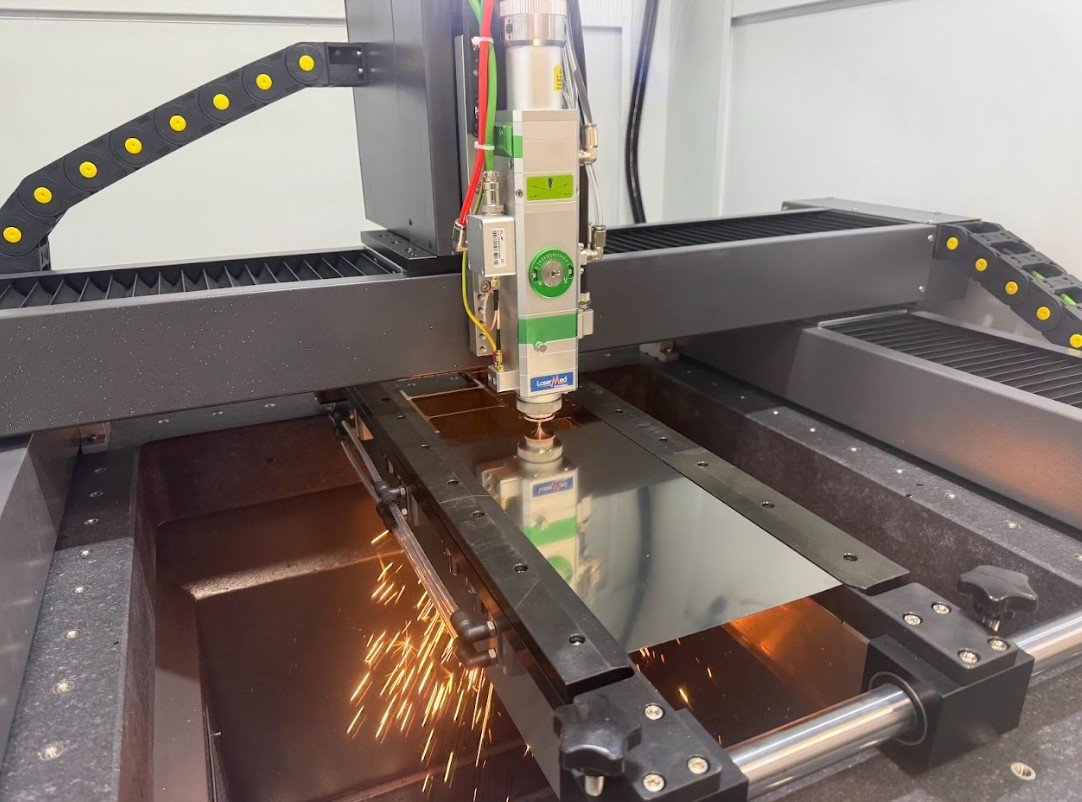

At LaserMed Technologies, we are always looking for ways to innovate and enhance our manufacturing capabilities. That's why we are excited to announce the latest addition to our high-tech arsenal: a state-of-the-art flatbed laser cutter. This advanced piece of machinery is a game-changer in the field of laser processing, and it's set to bring a host of benefits to our clients.

Key Features of Our Flatbed Laser Cutter:

Precision Cutting: The flatbed laser cutter is equipped with a highly focused laser beam that makes precise cuts with clean edges. This ensures that even the most intricate designs are cut to exact specifications without any material distortion.

Versatility: Capable of handling a wide range of metal materials, this machine allows us to serve diverse industries—from medical devices to aerospace components. Now with the capability to perform flat sheet cutting, we can efficiently process materials like Nitinol and stainless steel, enhancing our service offerings.

Expanded Material Capacity: Our flatbed laser cutter can handle materials up to 1/8” thick and provides up to 4 square feet of cutting surface, enabling us to take on larger and more diverse projects.

Speed: Designed for efficiency, our flatbed laser cutter significantly reduces production times. Its rapid processing capabilities enable us to complete large orders in a fraction of the time traditionally required, without sacrificing quality.

Consistency: With advanced cutting precision, this machine delivers consistent results, ensuring that every piece meets our rigorous quality standards.

Serving Our Clients with Enhanced Capabilities:

The addition of the flatbed laser cutter to our facility means that our clients can expect faster turnaround times for their projects, helping them to speed up their own production cycles and get their products to market quicker. This efficiency gain is crucial for industries where time-to-market can make a significant competitive difference.

Whether it's a prototype or full-scale production, we can now offer more customized options tailored to the specific needs of our clients. The new flatbed laser cutter not only enhances our capabilities but also reinforces our commitment to delivering top-tier precision and quality in every project. At LaserMed Technologies, we're not just keeping up with the industry standards; we're setting them.

Stay tuned for our next exciting update: we'll soon be introducing in-house metal 3-D printing capabilities to further expand our manufacturing versatility and innovation!